Product Description

Positioning Linear Stage

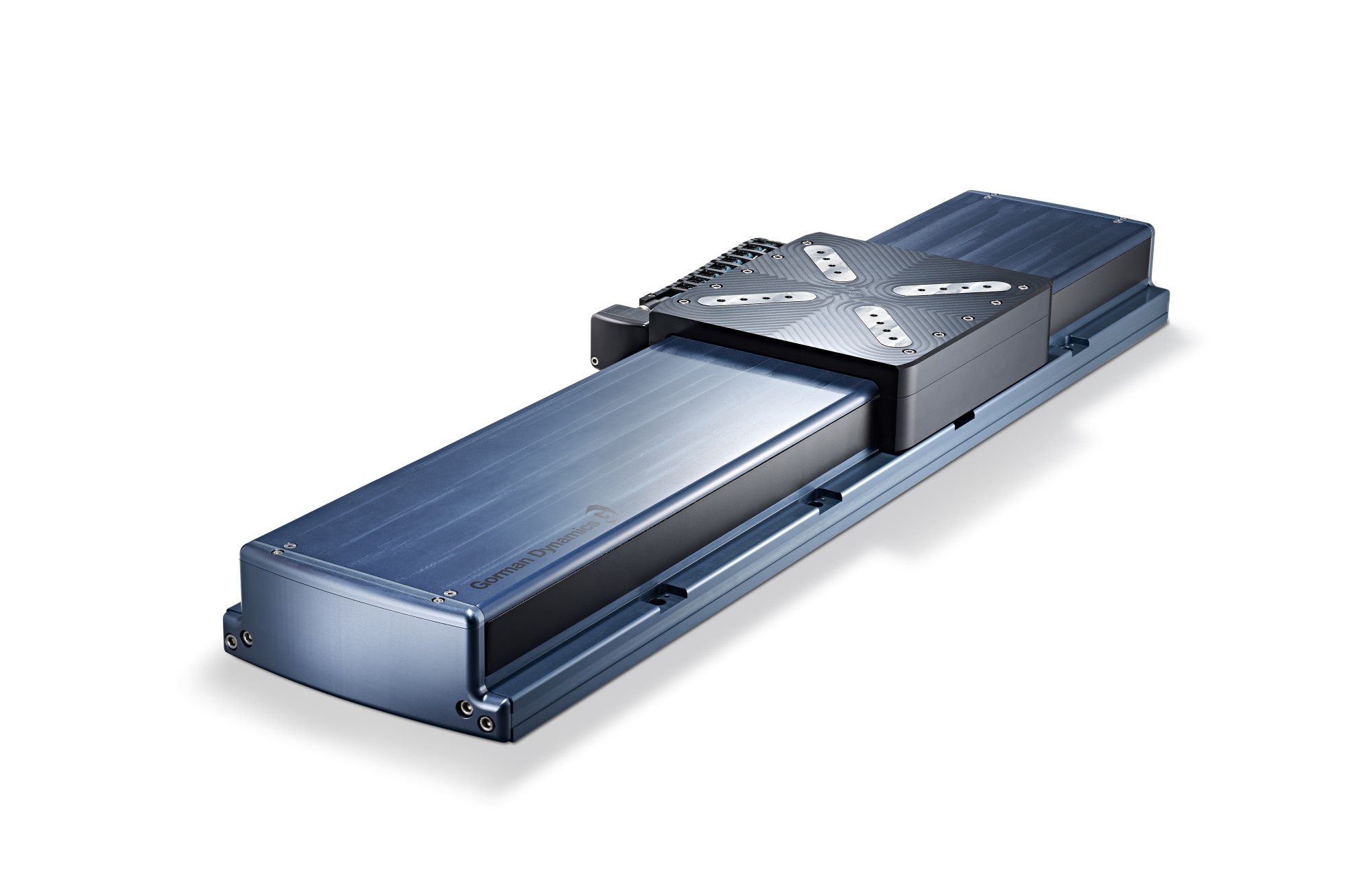

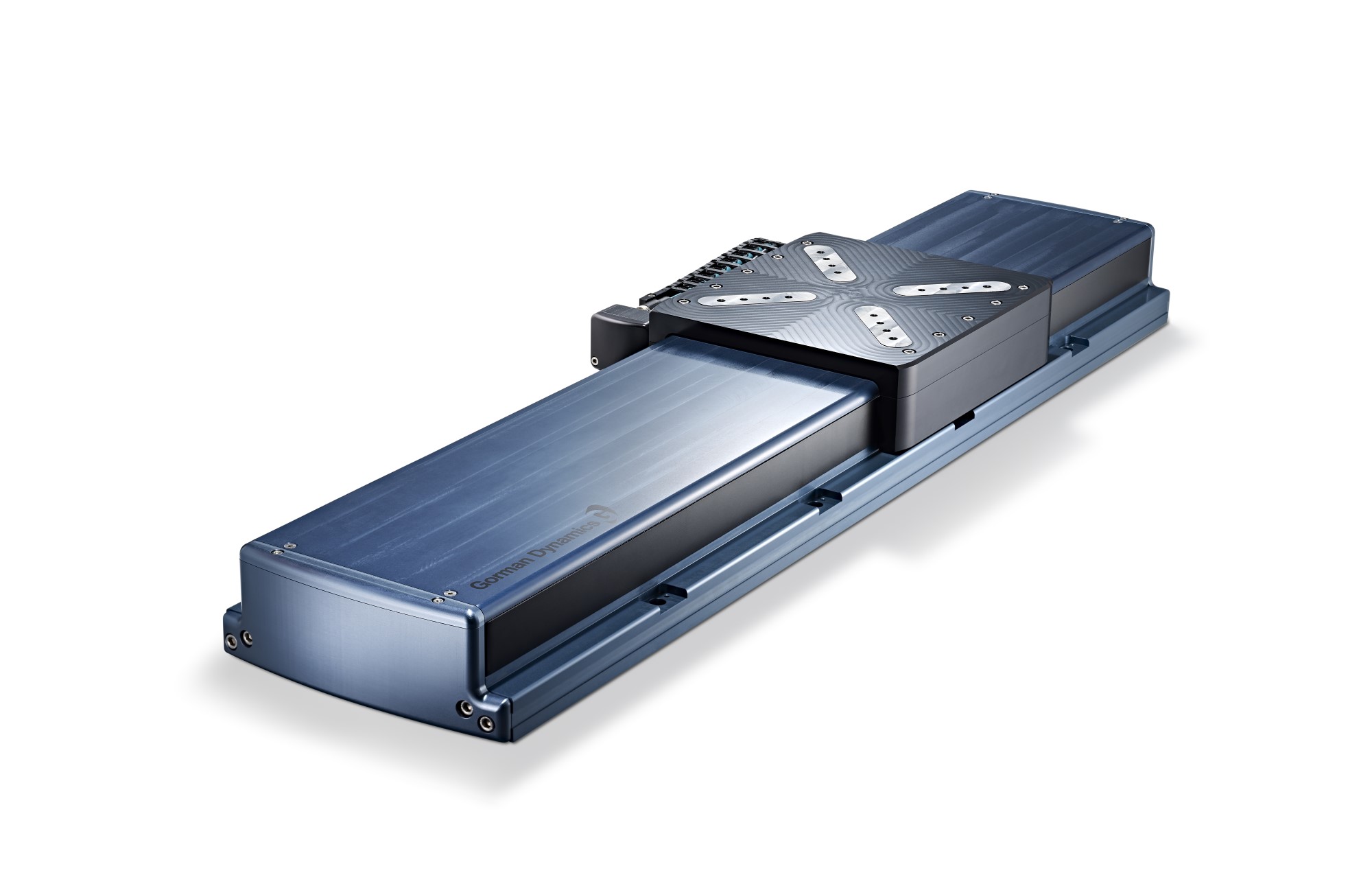

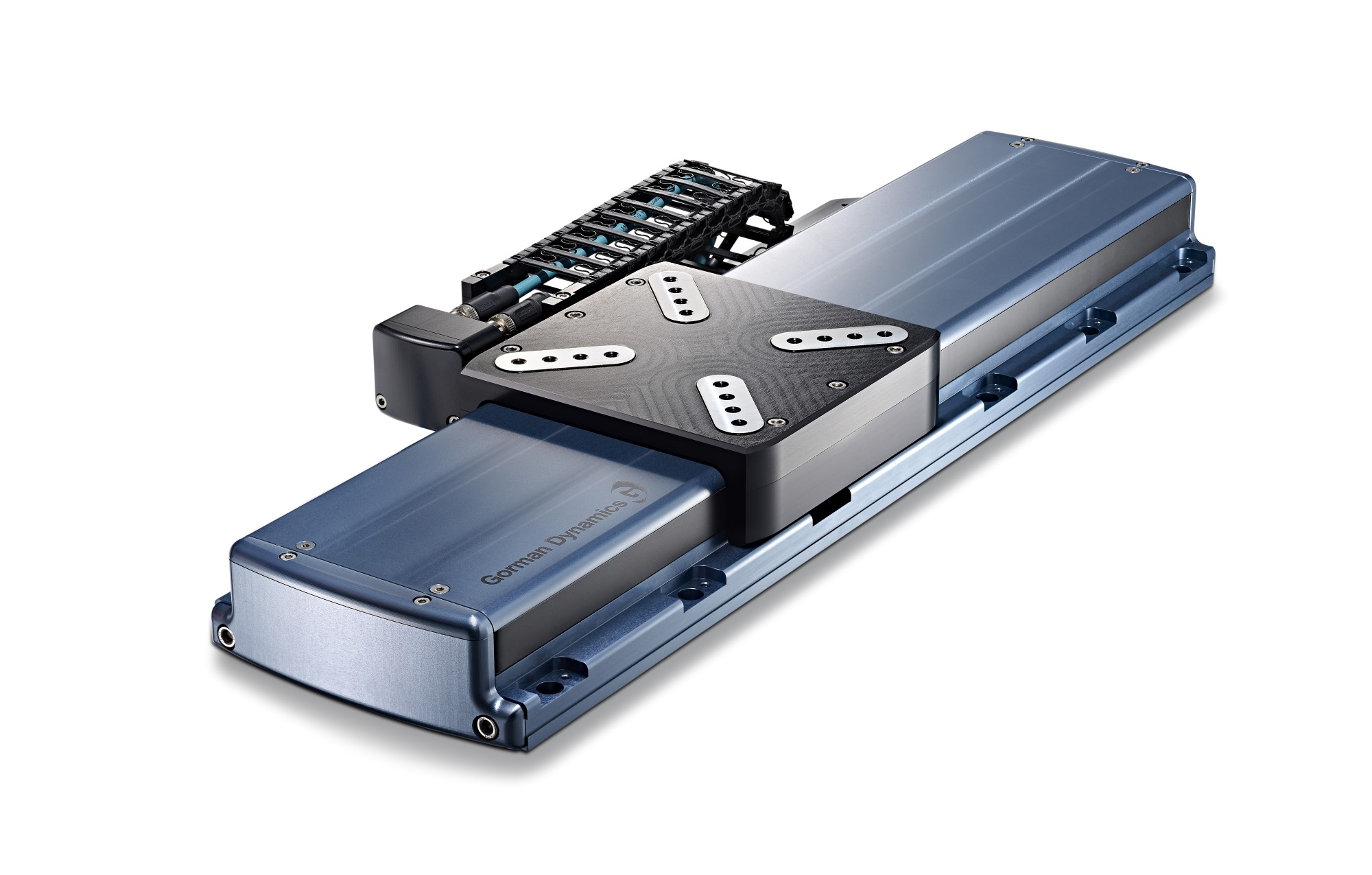

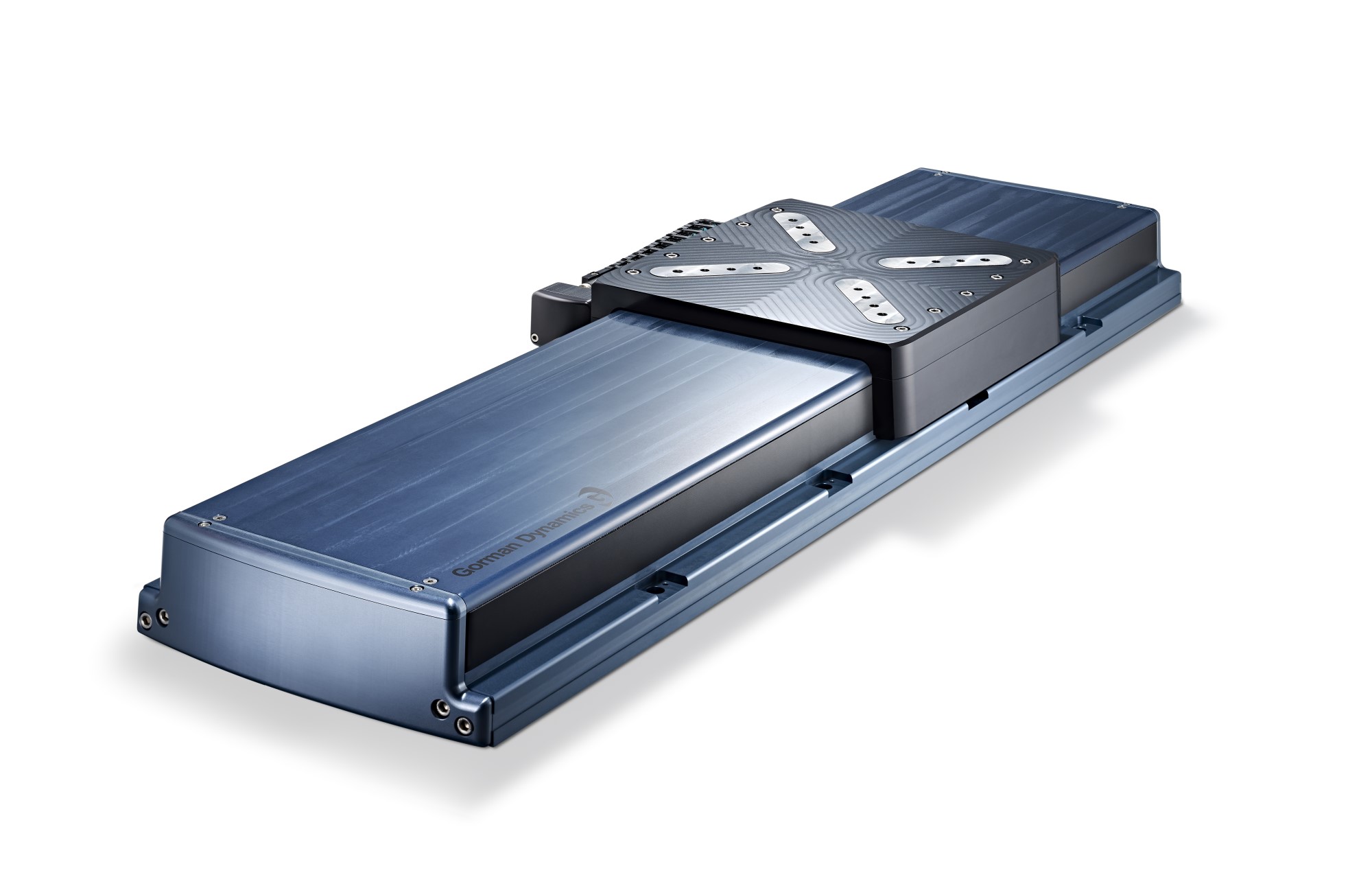

Introducing the G225-IC, the latest high-precision linear stage from Gorman Dynamics. This linear stage is engineered to withstand demanding industrial conditions, making it ideal for diverse industries. Its exceptional stiffness and utilization of high-quality components like powerful iron core linear motors, heavy-duty recirculating ball bearing guides, and precision absolute linear encoders give it a competitive edge. The G225-IC series stages are optimized with high-precision, non-contact absolute linear encoders, protected from debris by the stage sealing system. Precision recirculating linear bearings, along with meticulous machining and assembly, ensure excellent geometric performance specifications. Gorman Dynamics takes pride in delivering high-quality, dependable solutions. The G225-IC lives up to this reputation, offering unparalleled precision, durability, and safety for a wide range of industrial applications.

Iron Core Linear Motor

The G225-IC Series of High force linear stages utilizes iron core linear motors, offering a powerful and precise solution for various applications. These motors excel in delivering high power while maintaining exceptional precision and accuracy. With their ability to generate significant continuous forces, they prove to be ideal for demanding tasks where substantial force is required. Iron core linear motors also exhibit efficient heat dissipation properties, ensuring optimal performance and reliability even under high loading conditions. This feature prevents overheating and contributes to prolonging the motor's lifespan. Overall, the implementation of iron core linear motors, as seen in the G225-IC Series, provides a reliable and efficient solution suitable for a wide range of applications that demand both high power and precision.

Applications for Linear Stages

Precision linear stages play a critical role in various applications that necessitate high levels of accuracy and precision. These stages are frequently utilized in industries such as laser cutting, scanning, digital printing, and electronics assembly and inspection. They are also deployed in processes such as AOI (Automatic Optical Inspection) and laser micro-machining, which demand ultra precision and accurate scan motion. In medical and scientific equipment, precision linear stages are pivotal in ensuring accuracy and repeatability. In any industry or application, utilizing precision linear stages is crucial for achieving desired outcomes and delivering top-quality output.

Specifications G225-IC

| G225 Series | G225-IC-x-100 | G225-IC-x-150 | G225-IC-x-200 | G225-IC-x-250 | G225-IC-x-300 |

| Travel total (mm) | 100 | 150 | 200 | 250 | 300 |

| Position Accuracy uncalibrated (µm typ) | ±4 | ±6 | ±8 | ±9 | ±10 |

| Position Accuracy calibrated (µm) | ±1 | ±1 | ±1 | ±1 | ±1 |

| Resolution System (nm) | 5 | 5 | 5 | 5 | 5 |

| Repeatability Bi-directional (µm) | ±0.3 | ±0.4 | ±0.4 | ±0.4 | ±0.4 |

| Flatness / Straightness (µm) | ±2 | ±2.5 | ±2.5 | ±3 | ±3 |

| Yaw, Pitch & Roll (µrad) | ±25 | ±30 | ±35 | ±40 | ±45 |

| Maximum Velocity No Load (mm/s) | 2000 | 2000 | 2000 | 2000 | 2000 |

| Maximum Acceleration (m/s2) | 30 | 30 | 30 | 30 | 30 |

| Nominal Force (N) | 420 | 420 | 420 | 420 | 420 |

| Peak Force (N) | 840 | 840 | 840 | 840 | 840 |

| Load Capacity (kg) | 120 | 120 | 120 | 120 | 120 |

| Stage Weight (kg) | 24.1 | 25.7 | 27.2 | 28.8 | 30.4 |

| G225 Series | G225-IC-x-400 | G225-IC-x-500 | G225-IC-x-600 | G225-IC-x-800 | G225-IC-x-1000 |

| Travel total (mm) | 400 | 500 | 600 | 800 | 1000 |

| Position Accuracy uncalibrated (µm typ) | ±12 | ±14 | ±15.5 | ±17 | ±18 |

| Position Accuracy calibrated (µm) | ±1 | ±1 | ±1 | ±1.5 | ±1.5 |

| Resolution System (nm) | 5 | 5 | 5 | 5 | 5 |

| Repeatability Bi-directional (µm) | ±0.4 | ±0.4 | ±0.4 | ±0.5 | ±0.5 |

| Flatness / Straightness (µm) | ±4 | ±5 | ±6 | ±8 | ±9 |

| Yaw, Pitch & Roll (µrad) | ±55 | ±65 | ±75 | ±85 | ±90 |

| Maximum Velocity No Load (mm/s) | 2000 | 2000 | 2000 | 2000 | 2000 |

| Maximum Acceleration (m/s2) | 30 | 30 | 30 | 30 | 30 |

| Nominal Force (N) | 420 | 420 | 420 | 420 | 420 |

| Peak Force (N) | 840 | 840 | 840 | 840 | 840 |

| Load Capacity (kg) | 120 | 120 | 120 | 120 | 120 |

| Stage Weight (kg) | 33.6 | 36.8 | 41.1 | 46.4 | 52.8 |

| G225 Encoder Feedback Options |

Feedback (F1) Absolute |

(F1) Signal Period |

Feedback (F2) incremental |

(F1) Signal Period | In Position Stability |

| E1 - BISS-C Absolute - Single Track | BISS-C | 5 nm | +/- 1 µm | ||

| E2 - BISS-C Absolute - Single Track | BISS-C | 1 nm | +/- 0.5 µm | ||

| E3 - Incremental 1 Vpp - Single Track | 1 Vpp | 20 µm | +/- 0.5 nm | ||

| E4 - Incremental 1 Vpp - Single Track | 1 Vpp | 4 µm | < 0.5 nm | ||

| E5 - EnDat 2.2 Absolute - Single Track | EnDat 2.2 | 10 nm | +/- 1 µm | ||

| E6 - SSI Absolute - Single Track | SSI | 10 nm | +/- 1 µm | ||

| E7 - HIPERFACE Absolute - Single Track | HIPERFACE | 10 nm | +/- 1 µm | ||

| E8 - BISS-C Absolute + Incremental 3 Tracks | BISS-C | 20 nm | 1 Vpp | 20 µm | < 0.5 nm |

| E9 - EnDat 2.2 Absolute + Incremental 3 Tracks | EnDat 2.2 | 20 nm | 1 Vpp | 20 µm | < 0.5 nm |

| E10 - SSI Absolute + Incremental 3 Tracks | SSI | 20 nm | 1 Vpp | 20 µm | < 0.5 nm |

| E11 - HIPERFACE Absolute + Incremental 3 Tracks | HIPERFACE | 20 nm | 1 Vpp | 20 µm | < 0.5 nm |

| E12 - Custom Options Available | |||||

| E13 |

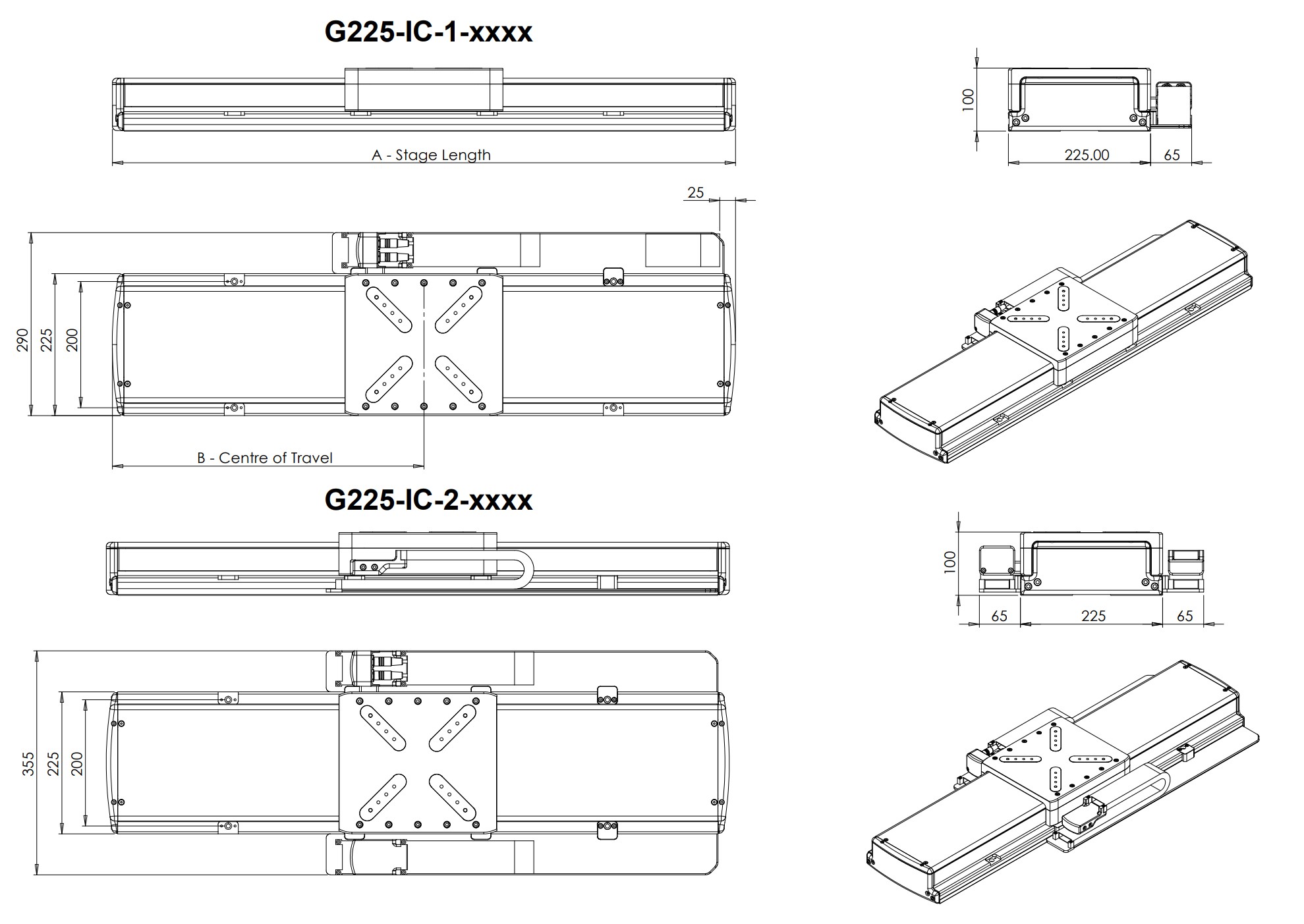

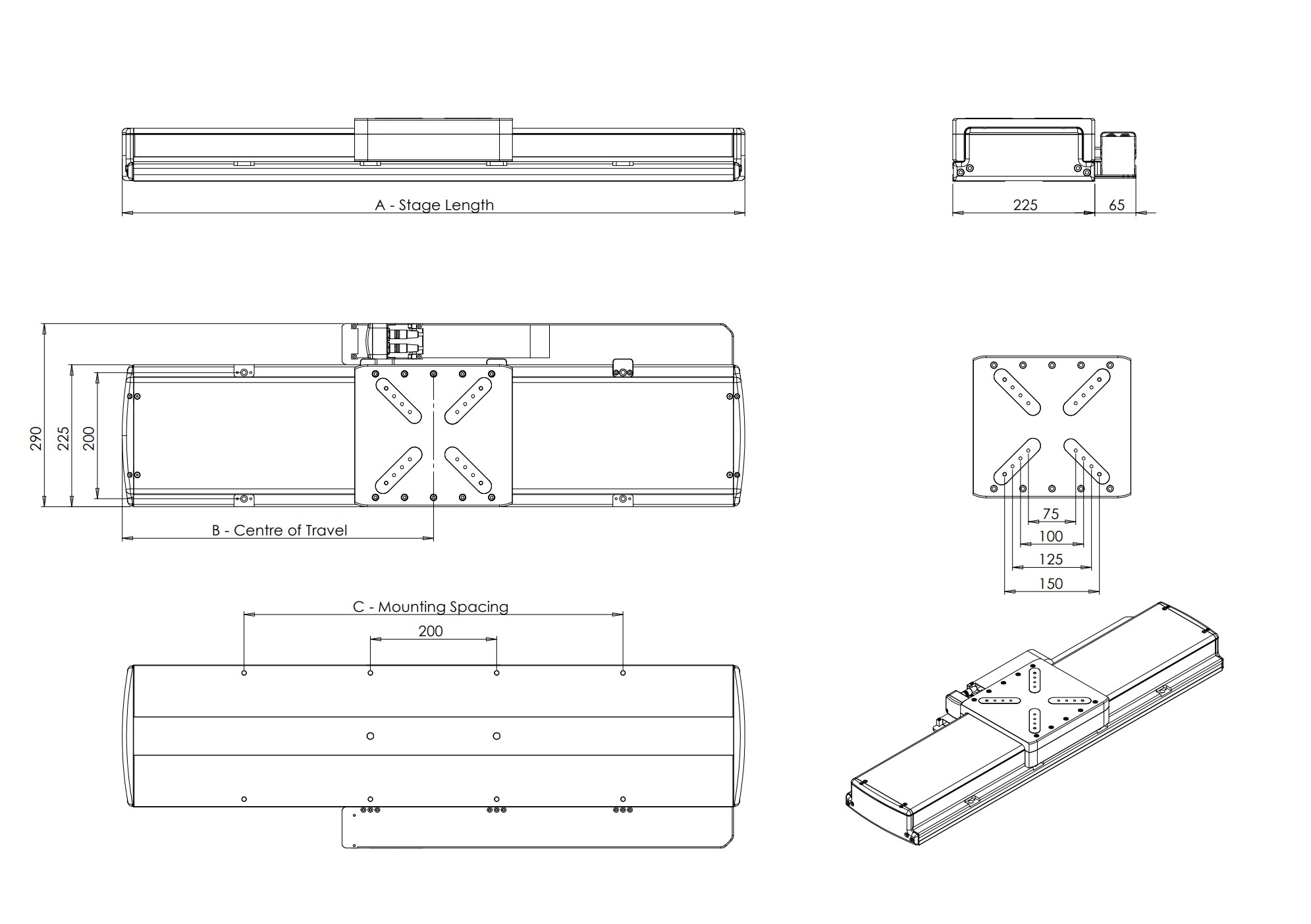

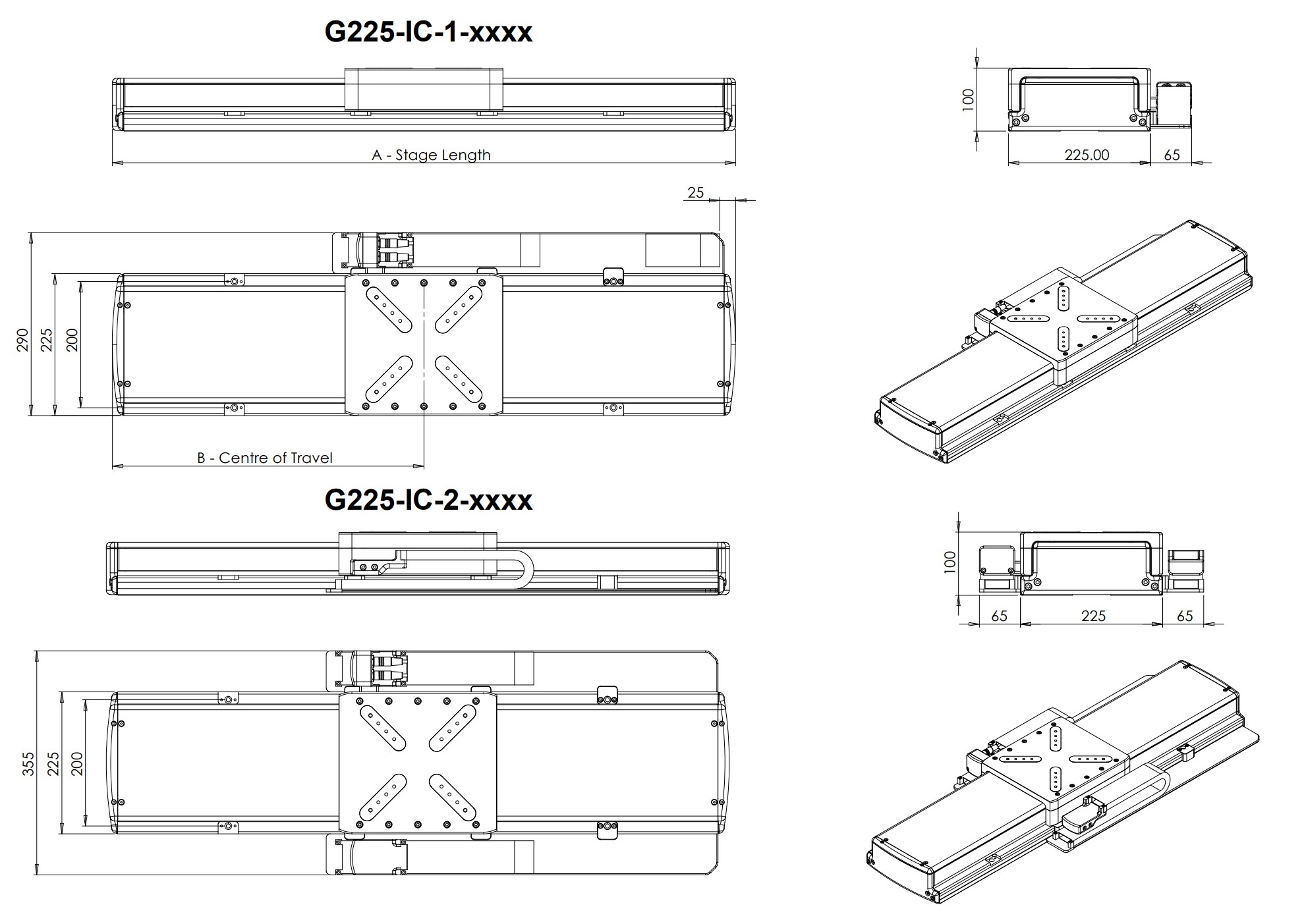

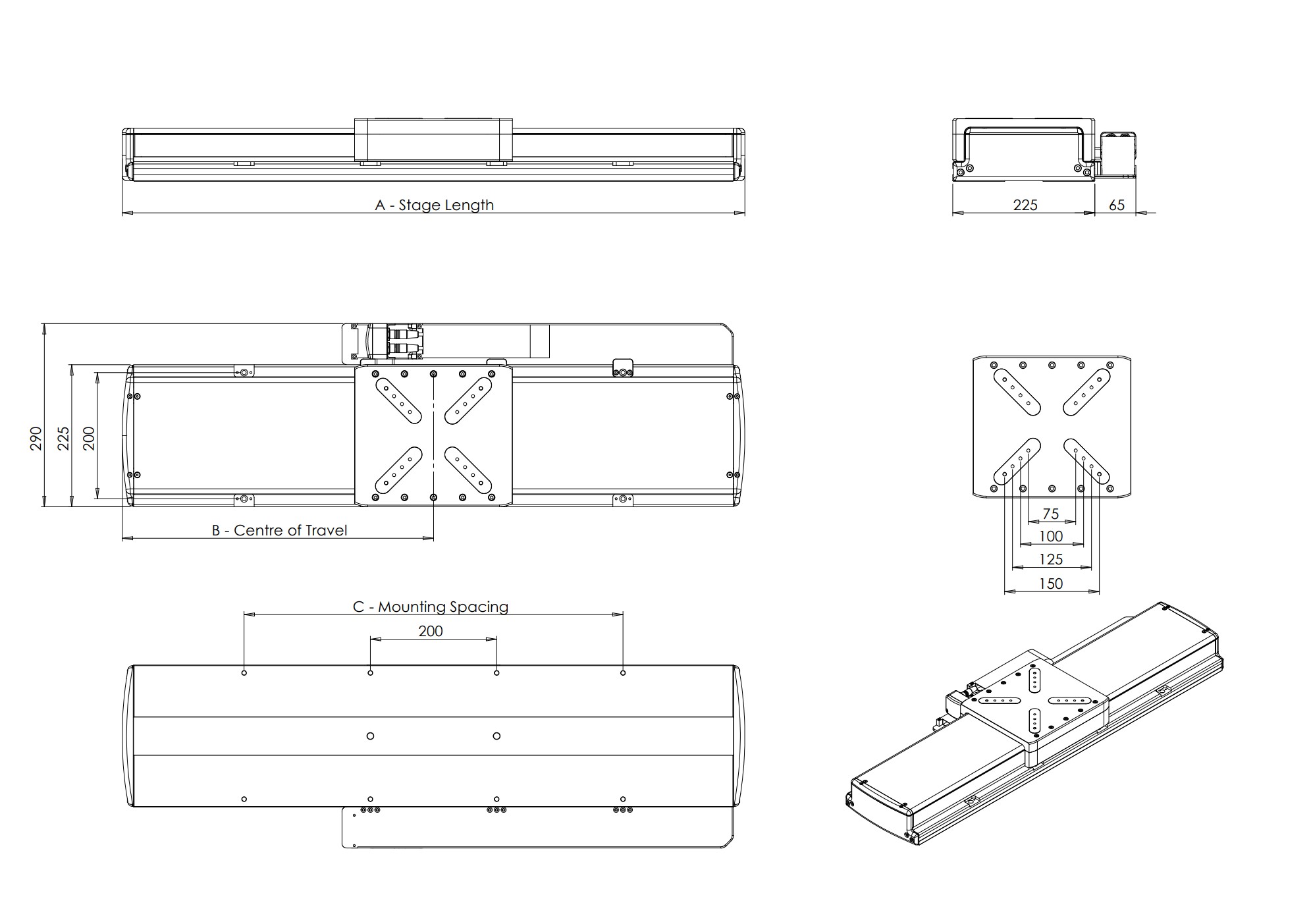

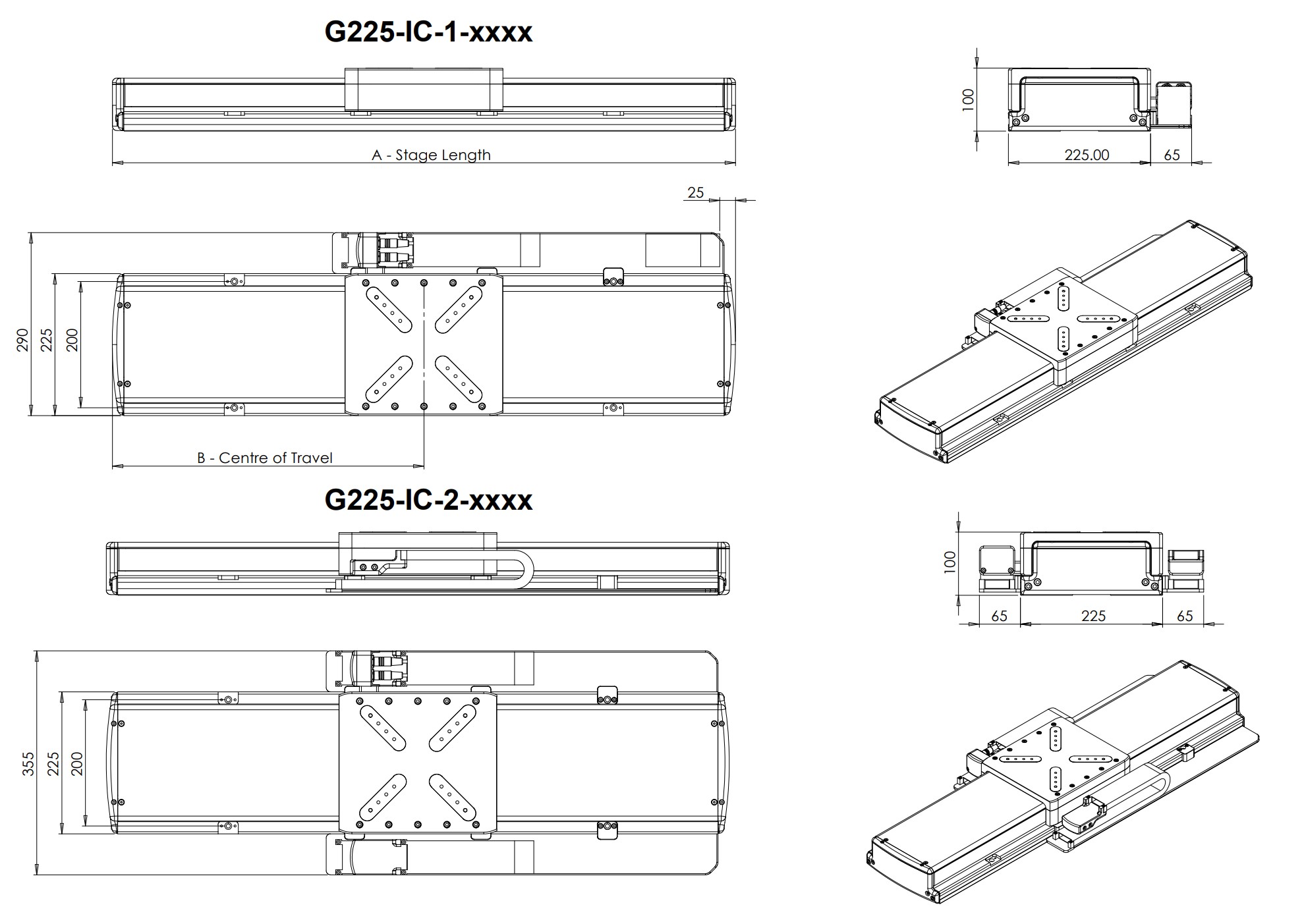

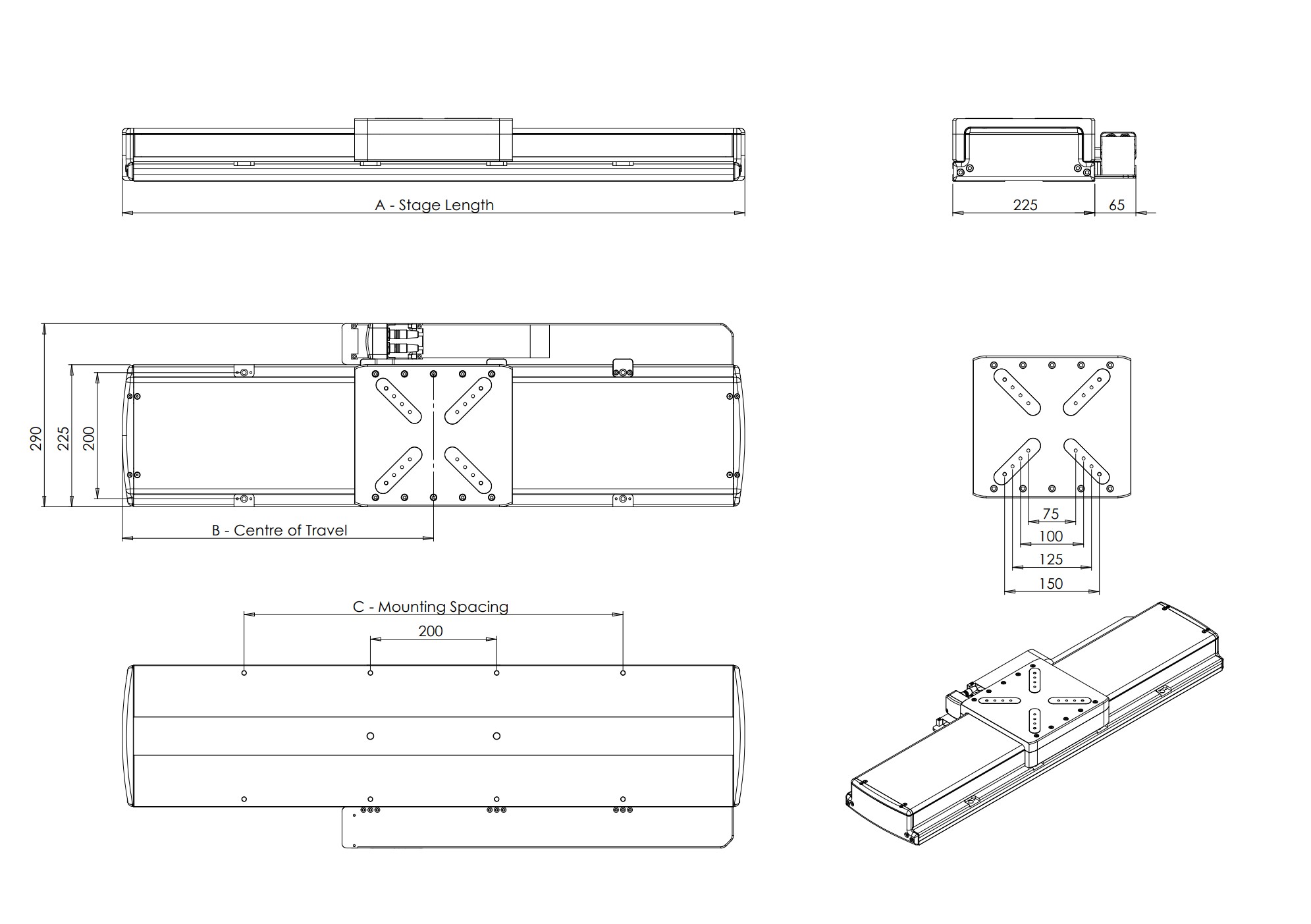

Product Dimensions

| G225 Dimensions (mm) | Travel | Hard Stop | A | B | C |

| G225-IC-x-100 | 100 | 116 | 486 | 245 | 200, 350 |

| G225-IC-x-150 | 150 | 165 | 536 | 270 | 200, 350 |

| G225-IC-x-200 | 200 | 216 | 586 | 295 | 200, 350 |

| G225-IC-x-250 | 250 | 266 | 636 | 320 | 200, 600 |

| G225-IC-x-300 | 300 | 316 | 686 | 345 | 200, 600 |

| G225-IC-x-400 | 400 | 416 | 786 | 395 | 200, 600 |

| G225-IC-x-500 | 500 | 516 | 886 | 445 | 200, 600, 800 |

| G225-IC-x-600 | 600 | 616 | 986 | 495 | 200, 600, 800 |

| G225-IC-x-800 | 800 | 816 | 1286 | 595 | 200, 600, 800, 1000 |

| G225-IC-x-1000 | 1000 | 1016 | 1386 | 695 | 200, 600, 800, 1000, 1200 |

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

Related Products

- Width 190mm

- Travels 100mm to 1200mm

- High Load Capacity 80 kg, 650 N

- Speed 2 m/s

- Continuous Force 120 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Iron Core Linear Motor

- Width 280mm

- Travels 100mm to 1200mm

- High Load Capacity 185 kg, 1850 N

- Speed 2 m/s

- Continuous Force 1140 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Iron Core Linear Motor

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語