Product Description

Positioning Linear Stage

Introducing the S165-IL, the newest standard linear stage series from Gorman Dynamics. Built to endure the most challenging industrial environments, this linear stage is perfect for a wide range of industries. The S165-IL stands out with its exceptional stiffness and premium components, including high-performance ironless linear motors, robust recirculating ball bearing guides, and precise absolute linear encoders. The series features high-precision, non-contact absolute linear encoders that are shielded from debris by a sealing system, ensuring optimal performance. Precision recirculating linear bearings, combined with meticulous machining and assembly, deliver outstanding geometric performance specifications. At Gorman Dynamics, we are dedicated to providing high-quality, reliable solutions for our clients, and the S165-IL exemplifies this commitment with its unmatched precision, durability, and safety for various industrial applications.

Ironless Linear Motor

The S165-IL Series offers a cutting-edge solution, leveraging the benefits of ironless linear motors. These motors provide high precision and accuracy, essential for many industrial applications. The absence of a ferromagnetic core in the stator eliminates cogging and any interaction between the stator and rotor magnetic fields, resulting in incredibly smooth and precise motion. This makes the S165-IL Series ideal for applications requiring high accuracy and precision. Additionally, its compact design and high power density make it perfect for use in space-constrained environments. Whether in semiconductor manufacturing equipment, medical devices, or robotics, the S165-IL Series delivers the precision and accuracy these industries demand.

Applications for Linear Stages

Precision linear stages are essential in applications requiring high accuracy and precision. Commonly used in industries like laser cutting, scanning, digital printing, and electronics assembly and inspection, these stages are vital for processes such as Automatic Optical Inspection (AOI) and laser micro-machining, which demand ultra-precise and accurate scan motion. In medical and scientific equipment, precision linear stages ensure accuracy and repeatability. Regardless of the industry or application, the use of precision linear stages is crucial for achieving desired outcomes and delivering top-quality results.

Specifications S165-IL

| S165 Series | S165-IL-x-100 | S165-IL-x-150 | S165-IL-x-200 | S165IL-x-250 | S165IL-x-300 |

| Travel total (mm) | 100 | 150 | 200 | 250 | 300 |

| Position Accuracy uncalibrated (µm typ) | ±4 | ±6 | ±8 | ±9 | ±10 |

| Position Accuracy calibrated (µm) | ±1 | ±1 | ±1.5 | ±1.5 | ±4 |

| Resolution System (nm) | 5 | 5 | 5 | 5 | 5 |

| Repeatability Bi-directional (µm) | ±0.4 | ±0.4 | ±0.4 | ±0.4 | ±0.4 |

| Flatness / Straightness (µm) | ±2.5 | ±3 | ±4 | ±5 | ±6 |

| Yaw, Pitch & Roll (µrad) | ±14 | ±14 | ±20 | ±23 | ±29 |

| Maximum Velocity No Load (mm/s) | 2000 | 2000 | 2000 | 2000 | 2000 |

| Maximum Acceleration (m/s2) | 30 | 30 | 30 | 30 | 30 |

| Nominal Force (N) | 87 | 87 | 87 | 87 | 87 |

| Peak Force (N) | 300 | 300 | 300 | 300 | 300 |

| Load Capacity (kg) | 50 | 50 | 50 | 50 | 50 |

| Stage Weight (kg) | 8.6 | 9.7 | 11.3 | 11.1 | 12 |

| S165 Series | S165-IL-x-400 | S165-IL-x-500 | S165-IL-x-600 | S165-IL-x-800 | S165-IL-x-1000 |

| Travel total (mm) | 400 | 500 | 600 | 800 | 1000 |

| Position Accuracy uncalibrated (µm typ) | ±12 | ±14 | ±15.5 | ±17 | ±18 |

| Position Accuracy calibrated (µm) | ±1.5 | ±2 | ±2 | ±2 | ±2 |

| Resolution System (nm) | 5 | 5 | 5 | 5 | 5 |

| Repeatability Bi-directional (µm) | ±0.4 | ±0.4 | ±0.4 | ±0.4 | ±0.4 |

| Flatness / Straightness (µm) | ±8 | ±9 | ±10 | ±12 | ±14 |

| Yaw, Pitch & Roll (µrad) | ±35 | ±40 | ±45 | ±50 | ±60 |

| Maximum Velocity No Load (mm/s) | 2000 | 2000 | 2000 | 2000 | 2000 |

| Maximum Acceleration (m/s2) | 30 | 30 | 30 | 30 | 30 |

| Nominal Force (N) | 87 | 87 | 87 | 87 | 87 |

| Peak Force (N) | 300 | 300 | 300 | 300 | 300 |

| Load Capacity (kg) | 50 | 50 | 50 | 50 | 50 |

| Stage Weight (kg) | 13.7 | 15.3 | 17 | 20.3 | 23.6 |

| S165 Encoder Feedback Options |

Feedback (F1) Absolute |

(F1) Signal Period |

Feedback (F2) incremental |

(F1) Signal Period | In Position Stability |

| E1 - BISS-C Absolute | BISS-C | 5 nm | +/- 1 µm | ||

| E2 - Incremental 1 Vpp | 1 Vpp | 20 µm | +/- 0.5 nm | ||

| E13 - Custom Options Available |

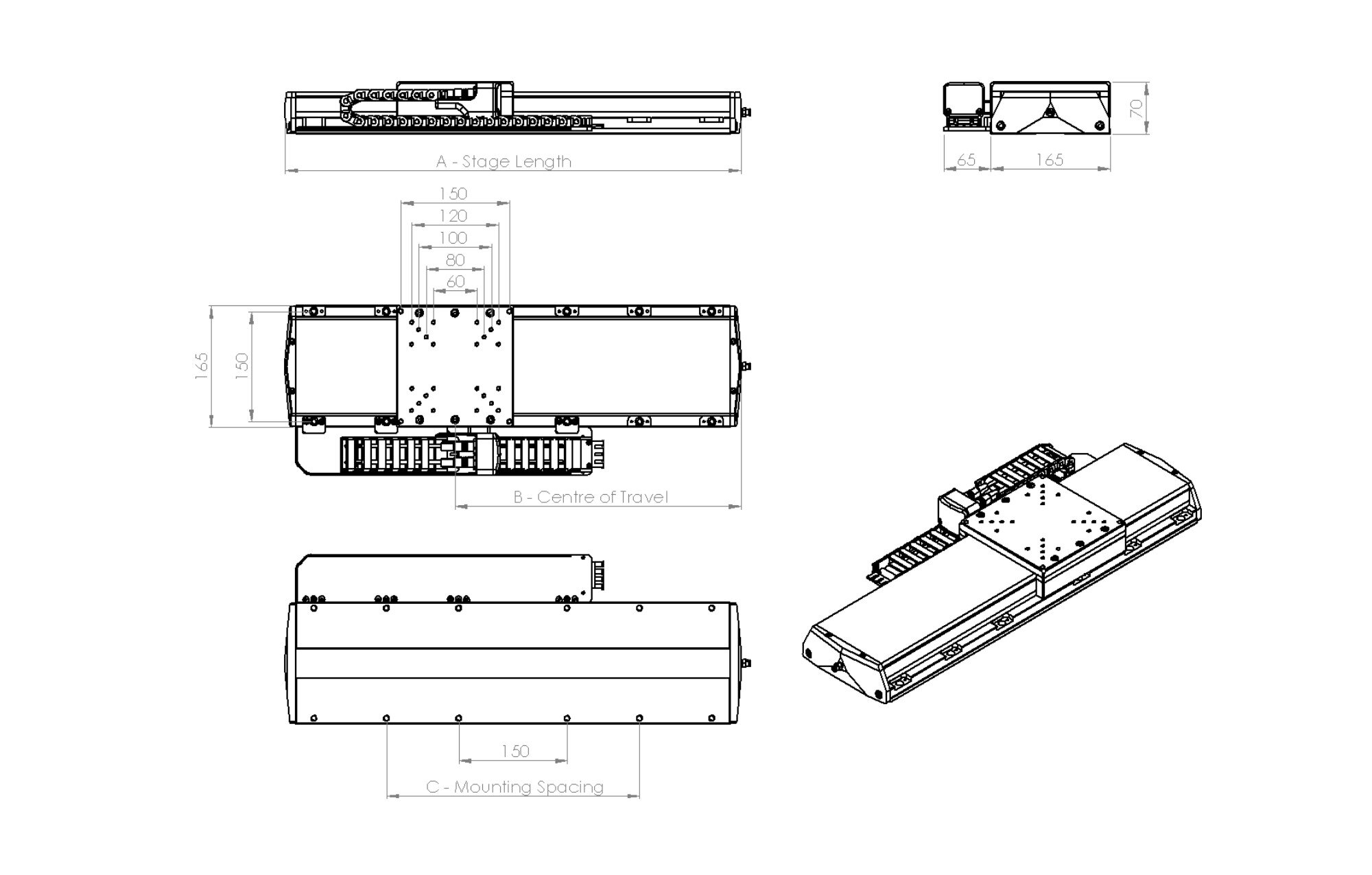

Product Dimensions

| S165 Dimensions (mm) | Travel | Hard Stop | A | B | C |

| S165-IL-x-100 | 100 | 116 | 330 | 165 | 150 |

| S165-IL-x-150 | 150 | 165 | 380 | 190 | 150 |

| S165-IL-x-200 | 200 | 216 | 430 | 215 | 150, 350 |

| S165-IL-x-250 | 250 | 266 | 480 | 240 | 150, 350 |

| S165-IL-x-300 | 300 | 316 | 530 | 265 | 150, 350 |

| S165-IL-x-400 | 400 | 416 | 630 | 315 | 150,350, 550 |

| S165-IL-x-500 | 500 | 516 | 730 | 365 | 150,350, 550 |

| S165-IL-x-600 | 600 | 616 | 830 | 415 | 150,350, 550, 750 |

| S165-IL-x-800 | 800 | 816 | 1030 | 515 | 150,350, 550, 750, 950 |

| S165-IL-x-1000 | 1000 | 1016 | 1230 | 615 | 150,350, 550, 750, 950, 1150 |

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

Related Products

- Width 115mm

- Travels 50mm to 400mm

- High Load Capacity 40 kg, 450 N

- Speed 2 m/s

- Continuous Force 39 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- Ironless Linear Motor

- Width 190mm

- Travels 100mm to 1200mm

- High Load Capacity 80 kg, 800 N

- Speed 2 m/s

- Continuous Force 87 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- Ironless Linear Motor

- Width 225mm

- Travels 100mm to 1200mm

- High Load Capacity 120 kg, 1200 N

- Speed 2 m/s

- Continuous Force 140 N

- High resolution absolute linear encoder

- Side cover to protect against particles

- High performance Ironless Linear Motor

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語