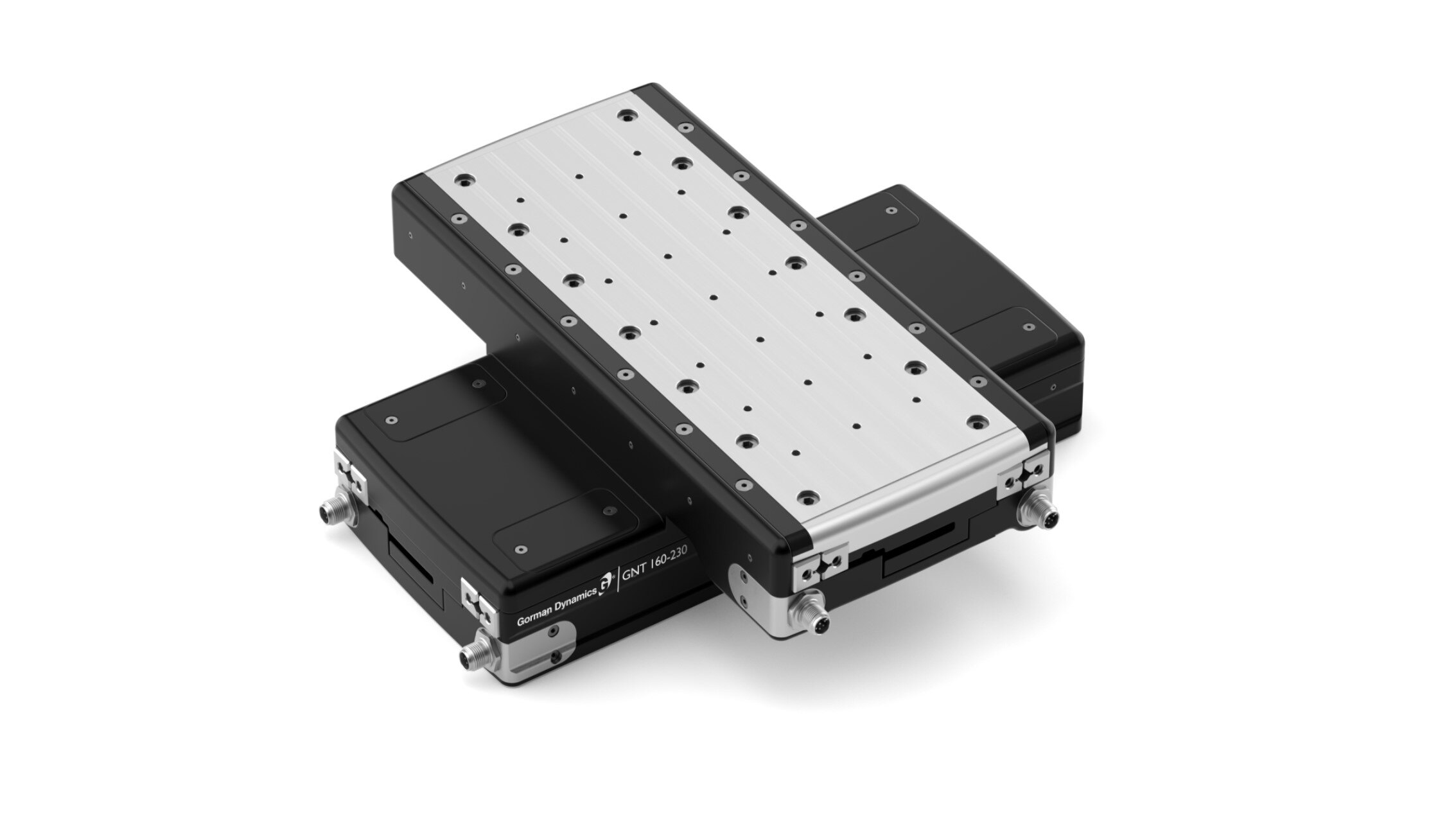

GNT160-230 Sub-Nanometer Precision Linear Stage

XY Linear Positioning Stage

- Width 160mm

- Travels 230mm

- High Load Capacity 20 kg, 200 N

- Speed 400 mm/s

- Peak Force 98 N

- High Precision Cross-roller bearings

- Ironless Linear Motor

- Ultra High resolution absolute and incremental encoder combination

- Sub-Nanometer 0.1nm incremental motion

Product Description

Positioning Linear Stage

The GNT160XY stages stand at the forefront of precision engineering, boasting unparalleled planar performance and impeccable geometric attributes. Their integrated two-axis design guarantees remarkable accuracy and efficiency. With the inclusion of rigid anti-creep crossed-roller bearings, these stages ensure stability and durability during operation. Moreover, their high-resolution position feedback system empowers users with detailed positional information, enabling fine-tuned control. To further enhance motion quality, the stages employ ironless linear motors, delivering exceptionally smooth and precise movements. From intricate manufacturing processes to advanced scientific research, the GNT160XY stages offer an ideal solution for applications that demand utmost precision and Sub Nanometer motion control. Experience the pinnacle of motion control with these state-of-the-art devices.

Ironless Linear Motor

The GNT160-IL Series is a cutting-edge solution that leverages the advantages of ironless linear motors. One of the key benefits of these motors is their high precision and accuracy, which are critical factors in many industrial applications. The absence of a ferromagnetic core in the stator eliminates cogging and any interaction between the stator and rotor magnetic fields. This produces incredibly smooth and precise motion, making it an ideal solution for applications where high accuracy and precision are essential. The GNT160-IL Series delivers unparalleled performance, making it a reliable and efficient solution for applications requiring a high degree of accuracy and precision. Additionally, its compact design and high power density make it ideal for use in applications where space is limited. Whether it is for semiconductor manufacturing equipment, medical devices, or robotics, the GNT160-IL Series delivers the precision and accuracy that these industries demand.

Applications for Linear Stages

Ultra-precision XY stages find wide-ranging applications across various industries where meticulous positioning and exceptional accuracy are paramount. In semiconductor manufacturing, these stages facilitate precise alignment during lithography and wafer inspection processes. In optics and photonics, they enable precise positioning for lens and mirror alignment in telescopes, microscopes, and laser systems. In the field of biomedical research, these stages aid in sample manipulation for high-resolution imaging and microscopy. Additionally, they are vital in the production of precision electronic components, such as printed circuit boards and microelectronics. Whether in research laboratories, industrial production lines, or advanced scientific experiments, ultra-precision XY stages play a pivotal role in achieving optimal performance and accuracy.

Specifications GNT160XY-IL-xxx

| GNT160 Series | GNT160XY-IL-210 | ||||

| Travel total (mm) (Hard Stops) | 230 | ||||

| Position Accuracy uncalibrated (µm typ) | ±3 | ||||

| Position Accuracy calibrated (nm) | ±120 | ||||

| Resolution System (nm) | 0.001 | ||||

| Repeatability Bi-directional (nm) | ±30 | ||||

| Minimum incremental motion (nm) | 0.1 | ||||

| Flatness / Straightness (µm) | ±2 | ||||

| Yaw, Pitch & Roll (µrad) | ±10 | ||||

| Maximum Velocity No Load (mm/s) | 400 | ||||

| Maximum Acceleration (m/s2) | 20 | ||||

| Nominal Force (N) | 29 | ||||

| Peak Force (N) | 98 | ||||

| Load Capacity (kg) | 20 |

| GNT160 Linear Encoder | Option | Type | Resolution | Repeatability |

| Linear Encoder (STD) | BISS C | Absolute | 0.0001µm | ±0.5µm |

| Linear Encoder (option) | BISS C + Inc | Absolute / Inc | 0.0001µm 0.001nm | ±30nm |

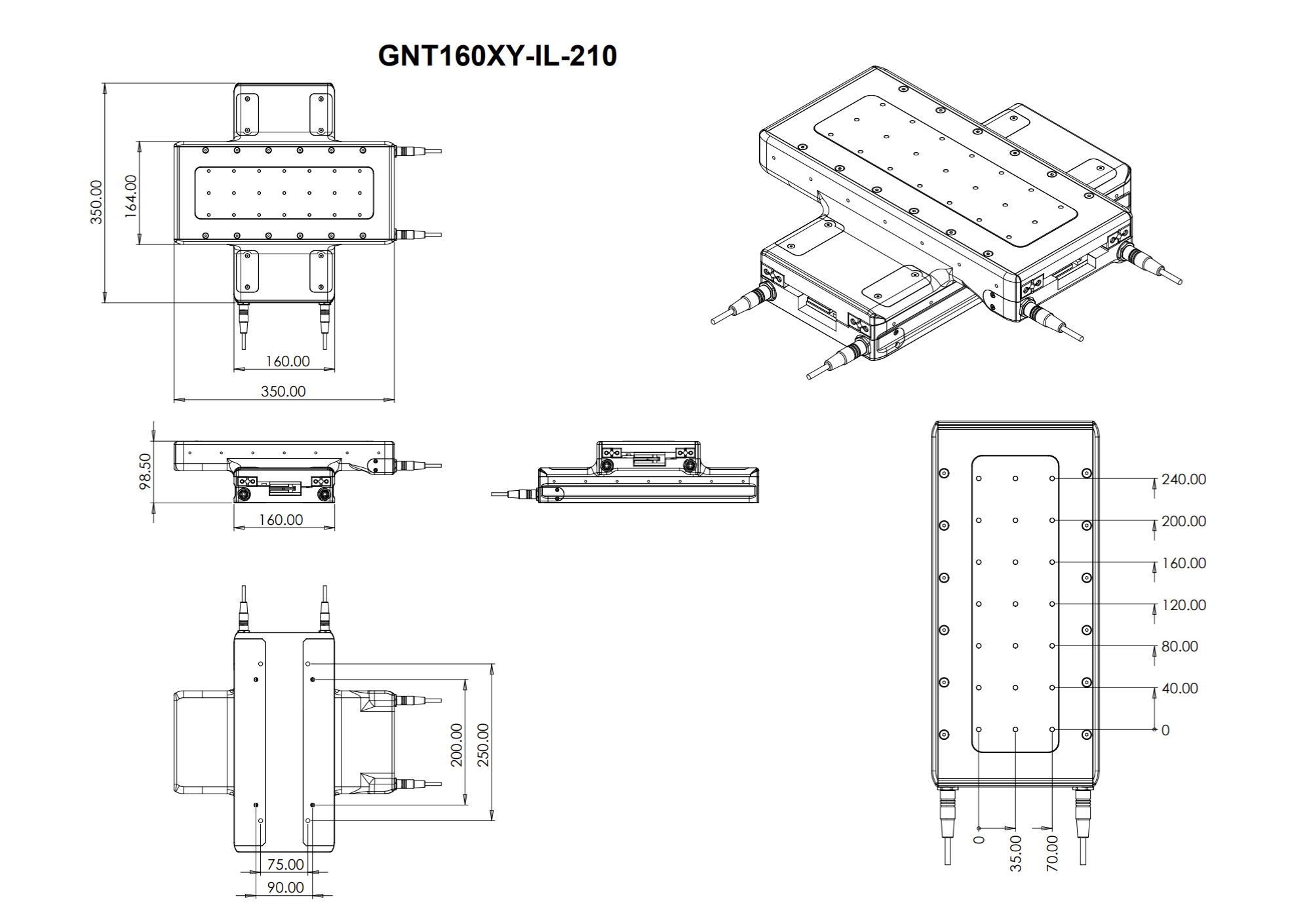

Product Dimensions

Ask An Engineer!

Quickly receive an answer to your question from a Gorman Dynamics engineer.

English

English

Español

Español

Français

Français

Deutsch

Deutsch

Svenska

Svenska

한국어

한국어

日本語

日本語